N-Form solid plastic panels

The economical choice for panelized formwork

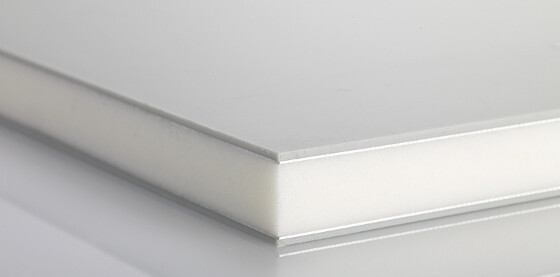

N-Form Panel

The N-Form Panel solid plastic panel is a very long-lived composite sheet – over 1,500 uses with 1 panel are documented. As a result the N-Form Panel is a very economical choice for panelized formwork. The patented layered panel is extremely robust, durable and enables top quality exposed concrete.

| Description | N-Form | |||||

|---|---|---|---|---|---|---|

| Type of Panel | N10 | N13 | N15 | N18 | N20 | N22 |

| Thickness (mm) | 9.9 | 12.9 | 14.9 | 17.9 | 19.9 | 21.9 |

| Tolerance (mm) | +0 / -0.1 | |||||

| Weight (kg/m2) | 8 | 10.5 | 13.36 | 16.1 | 14.5 | 19.6 |

| Width | 1220 | |||||

| Length | 2440 | |||||

| Module of Elasticity (N/mm2) | 6550 | 5550 | 5350 | 5250 | 5050 | 4550 |

| Flexural Strength (N/mm2) | 45 | 36 | 37 | 43 | 42 | 40 |

| Shear Resistance (N/mm2) | > 5.9 | |||||

| Thermal Properties | ||

|---|---|---|

| Conductivity | 0.2 | 0.2 |

| Expansion | 65 | 40 |

| Temperature Range | -15 Degrees to +85 Degrees | -15 Degrees to +85 Degrees |

| Other Properties | ||

|---|---|---|

| Water Absorption | 0% | 0% |

| Nailing | Same as Plywood | Same as Plywood |

| Scratch Resistance | 0.85 | 0.75 |

| Abrasion Resistance | > 27.000 | > 8.500 |

| Surface Hardness | 65 | 65 |

| Inflammability | B2 | B2 |

N-Form Panel Advantages

Long lasting and profitable

N-Form recyclable panel can be used up to 1500 times. This is many more uses than you get with plywood.

Manufactured from recycled plastic

As the plastic deposable epidemic continues. The polypropylene panel is manufactured from plastic waste and polypropylene to ensure strength and density is achieved.

Repairability or easy to repair

N-Form recyclable panel damages like scratches, tie holes and nail penetrations can be easily repaired.

Easy to clean

N-Form recyclable panel can be cleaned with a high pressure washer with up to 1,000 bar pressure.

Handling and flexibility

N-Form recyclable panel can be screwed, cut and nailed just like plywood. The panels are rigid but are flexible and able to be bent and shaped into unique shapes.

Excellent concrete finish

N-Form recyclable panel gives concrete finishes which are comparable with fair faced finishes.

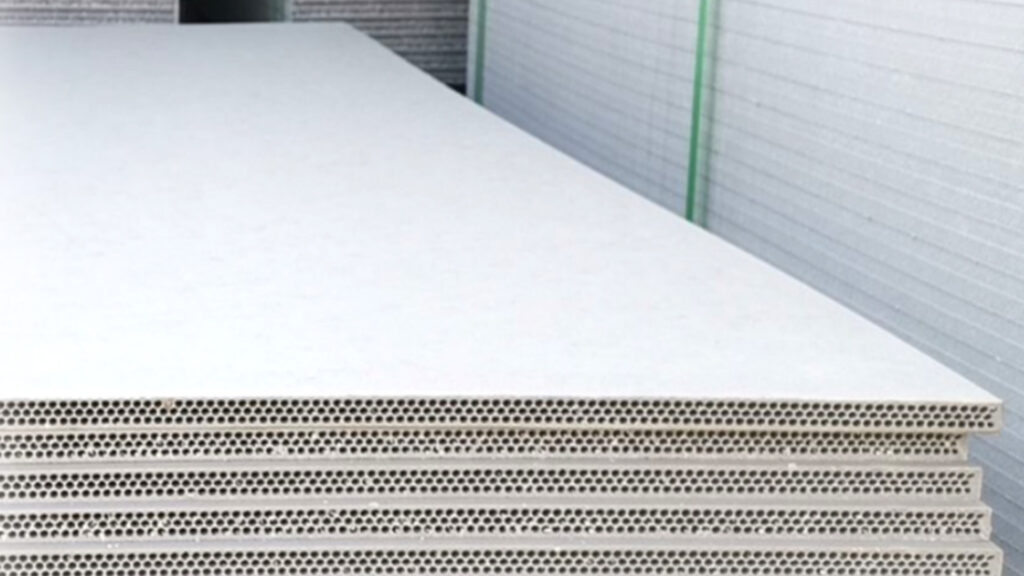

Eco-Form

Eco-Form is a plastic hollow board primarily used as a formwork material for concrete casting. It is composed of polypropylene plastic which gives its high durability, smooth surface, high heat and water resistance properties. As an alternative to traditional wooden formworks, i.e. phenolic boards, Eco-Form saves both on construction cost, through its reusability; and time, through its workability. While this lightweight board can be used multiple times, increasing work productivity, it also has a wide array of applications such as lightweight partitions, modular cabinets and shelves.

| Description | Eco-Form | ||

|---|---|---|---|

| Type of Panel | E12 | E15 | E18 |

| Thickness (mm) | 11.9 | 14.9 | 17.9 |

| Tolerance (mm) | +0 / -0.1 | ||

| Weight (kg/m2) | 7.68 | 9.6 | 11.52 |

| Width | 1220 | ||

| Length | 2440 | ||

| Module of Elasticity (N/mm2) | 2456 | 3070 | 3684 |

| Flexural Strength (N/mm2) | 71 | 60 | 56 |

| Shear Resistance (N/mm2) | > 5.9 | ||

| Item | Dimensions | Weight | Thickness | Pick-up price per board (VAT INC) |

|---|---|---|---|---|

| Ecoboard | 2440 mm x 1220 mm | 19 kg | 12 mm | Contact Us |

| 24 kg | 15 mm | |||

| 28 kg | 18 mm |

| Specifications | Ecoboard 18mm | Phenolic board 18mm or 3/4 inch | |

|---|---|---|---|

| Conservative | Maximized | ||

| Cost per piece* (4 x 8 ft) | Contact Us | ||

| No. of times used** | 80x | 100x | 6x |

| Cost per usage | Contact Us | ||

| Cost per sqm | Contact Us | ||

| Savings vs Phenolic board | 26% | 56% | - |

| Approx. # of times use to breakeven with phenolic board | 11x | - | |

| * Prices may be subject to change **Subject to on-site handling, proper usage, and maintenance | |||

| Specifications | Requirements | Inspection result | Testing basis |

|---|---|---|---|

| Hardness (D) | 20 pt | 66 | GB/T 2411 - 2008 |

| Impact strength (kl / sqm) | > 30 | 44.5 | GB/T 1043.3 - 2008 |

| Bending strength (MPa) | > 30 | 58.5 | GB/T 9341 - 2008 |

| Bending modulus (MPa) | > 3000 | 3.07 x 10 m3 | GB/T 9341 - 2008 |

| Heating rate crosswise (%) | ± 0.2 | - 0.11 | JG/T 418 - 2014 7.2.7 |

| Heating rate lengthwise (%) | ± 0.2 | - 0.125 | JG/T 418 - 2013 7.2.7 |

| Vicat softening point (dec C) | > 80 | 82 | GB/T 1034 - 2008 |

| Water absorption(%) | < 0.5 | 0.42 | GB/T 1633 - 2000 |

| * Using sample size: 1830 mm x 915 mm x 15 mm | |||

| Performance | Ecoboard formwork | PVC plastic formwork | Phenolic board |

|---|---|---|---|

| Water resistance | Good | Good | Poor |

| Surface abrasion resistance | Good | Good | Poor |

| Fire/heat resistance | Good | Good | Poor |

| Impact / drop strength | High | High | Normal |

| After absorbing water | No deformed | Minimal deformation | Deformed |

| Warping after use | No | Minimal warping | Yes |

| Weight ( kg/pc ) | 24 (15 mm) | 29 (15 mm) | 25 (15 mm) |

| Recyclability | Yes | Yes | No |

| Cost of use | Lowest | Low | High |

| Reusable time | Over 30x | Over 30x | 3-4x |

| Formwork stripping process | Easy | Easy | Difficult |

| Nailable and screwable | Yes | Yes | Yes |

| Can be cut / wooden saw | Yes | Yes | Yes |

| Scrap value | Some | Some | None |

| Material | Polypropylene (pp) | Polyvinyl chloride (pvc) | Wooden sheets |

| Size | 1220 x 2440 x 12/15/18 mm | 1220 x 2440 x 12/15/18 mm | 1220 x 2440 x 12/18 mm |

Eco-Form Panel Advantages

Cost efficient & reusable

To Can be reused 80 to 100x without difficulty. Cost is effectively lower compared to traditional wooden formworks.

Easy to use & transport

Formwork installation and removal is faster given the workability and lightweight properties of the plastic board, can be easily cut, nailed, screwed and drilled.

Water proof

High water resistance. No water absorption or bubbling even if left under wet conditions.

Surface abrasion resistant

Surface is smooth and can withstand abrasion especially during stripping / dismantling after concrete is dried, thereby allowing a smoother concrete finish.

Heat / chemical resistant

Suitable under a wide range of weather conditions (-10 to 90 deg C). Surface is resistant to chemicals and other substances that would otherwise damage traditional formworks.

Environmental friendly

No toxic substances used to make the plastic board (lead, mercury, cadmium, etc).

Minimal maintenance

Can be stored over a long period of time without preventive maintenance. Surface is easily cleaned by washing in order for multiple use.

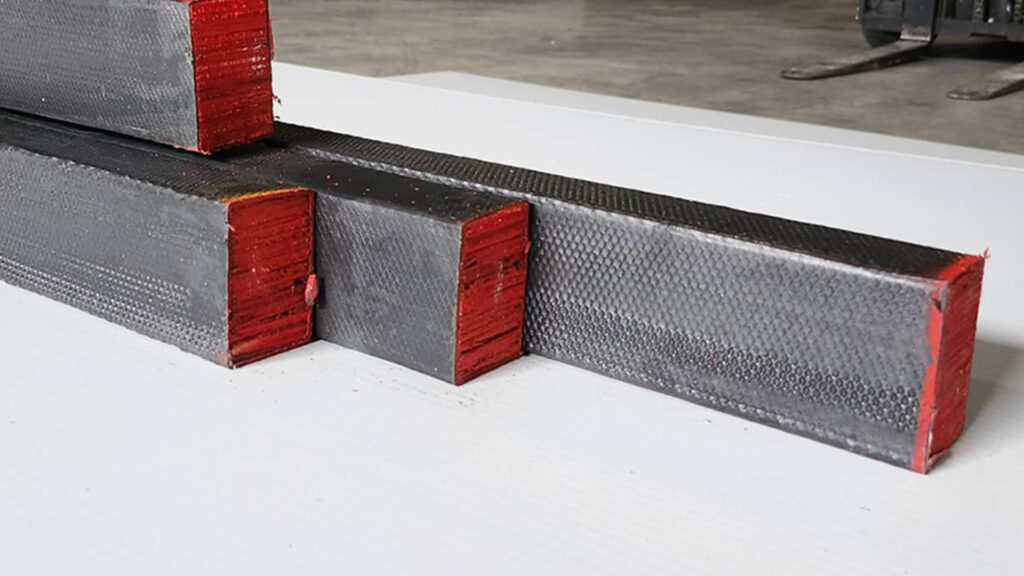

Ecobeam

Ecobeam is a multi-functional engineered wood laminated beam primarily used for construction formwork beams or bracing and wood architectural products (door, stairs, planks, louvers). The Ecobeam is composed of compressed multi-layered thin plywood wrapped in a strong coating. It is your cost-effective and lightweight alternative solution in replacement of traditional formwork support systems (lumber or GI pipes) and raw lumber used for finishing architectural materials.

| Width x Height | Length | Weight (per linear meter) |

|---|---|---|

| 50 x 70mm | 2.4 m | 2.2 kg |

| 3.0 m |

Ecobeam Advantages

Cost Efficient

Superior reusability over 50x (long life span)

Lightweight & easy to handle

No heavy equipment needed; can be nailed, sawed, screwed and cut

Saves time

Faster assembly & integration with existing formwork systems (for columns, beams, slabs, etc)

Durable

Anticorrosion, fire-resistant, water-resistant, and can withstand shocks and weights

Multifunctional

Can be used for furnitures, doors, windows, pallets, packaging, etc.